Energy efficiency has never been more important. Every business has a need for it, every government has an agenda for it, and every vendor wants to tell you how they build it into their products.

As manufacturers of some of the most efficient air-conditioning units on the market, Fujitsu knows more than most about energy efficiency. But it occurred to us that it is not just about the products. Every installer, specifier, contractor and architect is now expected to help tenants and users to get the most efficient use out of their air-conditioning systems. And there are a number of ways in which efficiency can be improved.

So we have put together a short summary of the key factors that can affect the efficiency of your air conditioning. If this is the first time you have really considered this issue, we hope this will be a really useful guide and perhaps something of an eye opener to how energy efficiency works in the air-conditioning world. On the other hand, if you are an experienced HVAC practitioner, you will nevertheless appreciate a checklist to make sure you are covering every option and achieving the best levels of efficiency for your customers.

Energy efficiency can be impaired or improved (depending on your viewpoint) by a number of factors, including the following:

1. Planning ahead

It is always worth ‘planning ahead’ when considering the air conditioning of a space. Is it going to be for open plan usage or will it be zoned at a later date? Where will the equipment be sited?

What is the future usage going to be?

Consideration of all these points will assist in selecting the right air-conditioning equipment for the application intended. Smaller ducted units will allow for future zoning of the space, whereas cassette type indoor units will restrict this.

Spare a thought for the location of the indoor and outdoor units since excessive pipe runs should be avoided as a severe drop off in performance will be experienced. If considering the use of heat recovery VRF systems, try and create a balance of indoor units that require heating with that of indoor units requiring cooling, in addition to giving consideration to building diversity.

Always provide suitable service access for engineers to carry out effective system maintenance in accordance with the manufacturer’s recommendations.

2. Selection/sizing

Correct sizing and selection of air-conditioning equipment is key to achieving optimum energy efficiency.

Over-sizing in itself doesn’t render the system operationally inefficient. However, increased power consumption over the lifetime of the system can prove otherwise. Alternatively, under-sizing the system can result in excessive operation during normal system lifetime and can cause premature failure. Of course, where possible, select A/A rated equipment with the latest in DC inverter technology.

Ensure consideration is given to using the correct UK design criteria when choosing equipment, as nominal capacities normally quoted within manufacturers’ literature can result in the incorrect sizing of the equipment. It is also important to adhere to the manufacturers’ recommended pipe sizes and maximum pipe lengths as system capacity will reduce significantly if these are exceeded.

3. Control/set point

The most energy-efficient air conditioning systems installed in any application can be rendered energy inefficient if not controlled in the correct manner. Most of today’s control options can greatly increase the efficiency of an air-conditioning system. Control of operation times and set-point temperatures are the most basic and fundamental of control functions that will enhance system efficiency.

However, depending upon size and type of air conditioning system installed, more sophisticated control systems should be considered so that additional functions such as ‘night set back’, centralised set-point control and occupation detection facilities can be utilised to improve operation. It is always worth asking users how they expect to use the space that is to be air conditioned. Also consider options available on air conditioning systems, such as Energy Saving and Economy modes.

Always be aware of the competition by users to either have the maximum heating temperature set point compared to the lowest cooling set point. Centralised control should be considered for this instance as constant adjustment of the set point will only result in erratic operation of the system and a reduced level of efficiency, not to mention the most uncomfortable conditioned space.

Finally, avoid the possibility of independent systems ‘fighting’ against each other whilst in different operating modes, ie one system heating whilst another is cooling in the same space.

4. Refrigerant charge

Paying attention to refrigerant charge is important for any air-conditioning system. Undercharging will result in the starvation of refrigerant within the system, in turn reducing the ability of the refrigerant to absorb the required amount of energy to satisfy the heating or cooling demand of the conditioned space. Operation times will subsequently increase and defrost cycles will become more frequent creating higher risk of system failure and reduced capacity and space temperature control.

If a system is undercharged, always check for leaks within the pipe work and equipment and repair or replace as necessary before re-charging. Also be aware that some refrigeration systems may also be subject to routine leakage testing requirements under the F-gas regulation (EC Regulation No. 842/2006 on Certain Fluorinated Greenhouse Gases).

Frequently, these issues stem from poorly planned installation in the first place that make inspection and maintenance difficult or even impossible. If the filter or coils cannot be inspected or cleaned, the system’s efficiency will be dramatically reduced as the airflow across the coils becomes restricted. Over time this will result in costly repairs to the condenser as the compressor will inevitably fail.

5. Insulation

Poorly insulated and/or damaged insulation on pipe work breaks the vapour seal allowing condensation to form on the pipe. This condensation can soak into the insulation destroying the thermal insulation properties. The resulting exposed pipes will decrease the system’s efficiency.

Many split system expansion devices are located in the outdoor unit and poorly insulated pipe work can affect the efficiency of the air conditioning system. Exposed pipes will act like a heat exchanger and absorb or reject energy before the refrigerant reaches the indoor or outdoor unit reducing the performance of the air conditioning system. Always ensure pipe work insulation is of the correct quality and standard as recommended by the manufacture and/or in line with good refrigeration installation practice.

6. Air distribution

Good air distribution is key to an effective and efficient air-conditioning system. Where applicable, particular attention must be paid to effective and correct duct work design so as not to impair airflow over the system.

Consider the distribution of air into the conditioned space. Avoid ‘dead zones’ and draughts as they may lead to the occupants using the controls erratically. Always consider the usage of the space and the furnishing within the space to avoid any possible ‘short circuiting’ of airflow.

7. Servicing and access

Too often, system maintenance is neglected – and even the most efficient air-conditioning systems will not fulfill their operating potential if not serviced regularly.

Regular maintenance checks will ensure your air-conditioning system operates as efficiently as possible. Energy consumption can increase by as much as 60% as a result of replacing poorly maintained or dirty components. Simple routine maintenance such as checking and cleaning fans, filters, coils/heat exchangers and any associated duct work will maintain system efficiency.

Frequently, poor planning with regards to system location makes it impossible for service engineers to gain safe and suitable access to units on routine maintenance visits. Reference should always be made to the manufacturer’s recommendations to location and service space requirements as detailed within installation and maintenance manuals.

8. Usage & the people factor

Understanding how and when to use your airconditioner is also a pre-requisite for energy efficiency. Basic functions such as fan speed and louvre angle can be adjusted to improve efficiency. Use external shading to reduce the amount of light/heat entering a space, and louvres can be retrofitted to buildings to provide shade during summer whilst allowing lower winter sun to penetrate the area. Blinds can also be angled to reduce solar heat gains whilst reflecting light onto walls and ceilings to reduce demand for electric lighting.

While these are all things you can do to boost efficiency, all this work can be undone by the ‘human factor’ – ie if occupants leave doors and windows open.

The answer is not usually to issue a set of rules, but to encourage staff involvement by demonstrating how they can be more in control of their own environment. Explain how thermostats operate and give guidance on recommended operating temperatures and on how to set heating or cooling units correctly. Display instructions on individual units and ensure that remote controls are accessible. It has also been observed that where other energy saving measures are in place [eg PIR-activated lighting], users are more aware of their responsibilities and react by being less wasteful. This is more a people issue than a technical one, but vital to the overall performance and efficiency of a system.

Featured Products

Midea Xtreme Save Series DC Inverter Wall Mounted Air Conditioner 1 ton | MSAGB-12HRFN8

Rated 4.76 out of 5

In stock

Mitsubishi Heavy Industries 0.75 Ton DC Inverter Wall Mounted Air Conditioner | SRK25ZSP-W

In stock

Midea Ceiling Cassette 4.0 ton Air Conditioner – MCD1-48HRN1

In stock

Midea Ceiling Cassette 1.5 ton Air Conditioner – MCA-18HRN1

In stock

Mitsubishi Electric 1.6 Ton DC Inverter Wall Mounted Air Conditioner | MSZ-HJ50VA

In stock

Mitsubishi Electric 2 Ton DC Inverter Wall Mounted Air Conditioner | MSZ-HJ60VA

In stock

Midea Breezeless E series 1.5 ton Full DC Inverter Wall Mounted Air Conditioner | MSCB1CU-18HRFN8

In stock

AURA 2 ton Wall Mounted Air Conditioner (WiFi Control) | AU24NSWAC

In stock

Skyworth 1 ton DC Inverter Wall Mounted Air Conditioner | SMVH12B-WiFi

In stock

Mitsubishi Heavy Industries 1.6 DC Inverter Wall Mounted Ton Air Conditioner | SRK50ZS-W

In stock

Skyworth 1.5 ton Wall Mounted Air Conditioner | SMFH18B

In stock

Blue Star 1.5 ton DC Inverter Wall Mounted Air Conditioner | HW18HXYFCN-00

In stock

Midea Breezeless E series 1 ton Full DC Inverter Wall Mounted Air Conditioner | MSCB1BU-12HRFN8

In stock

Rated 5.00 out of 5

Midea Breezeless E series 1.5 ton Full DC Inverter Wall Mounted Air Conditioner | MSCB1CU-18HRFN8

In stock

Midea BreezeleSS+ series 1 ton DC Inverter Wall Mounted Air Conditioner | MSFAAU-12HRFN8

In stock

Midea DC Inverter type Tower Floor Standing Air Conditioner 2 ton

In stock

Midea DC Inverter Wall Mounted Air Conditioner 1.5 ton (Xtreme Save Series) | MSAGC-18HRFN8

In stock

Midea DC Inverter Wall Mounted Air Conditioner 2 ton (Xtreme Save Series) | MSAGDU-24HRFN8

In stock

Midea Floor Standing Air Conditioner 2 ton (MFPA400-24ARN1)

In stock

Midea Floor Standing Air Conditioner 4 ton (MFGA-48HRN1)

In stock

Midea Penrose Air series 1 ton DC Inverter Wall Mounted Air Conditioner | MSXTBU-12HRFN8

In stock

Midea Penrose Air series 1.5 ton DC Inverter Wall Mounted Air Conditioner | MSXTCU-18HRFN8

In stock

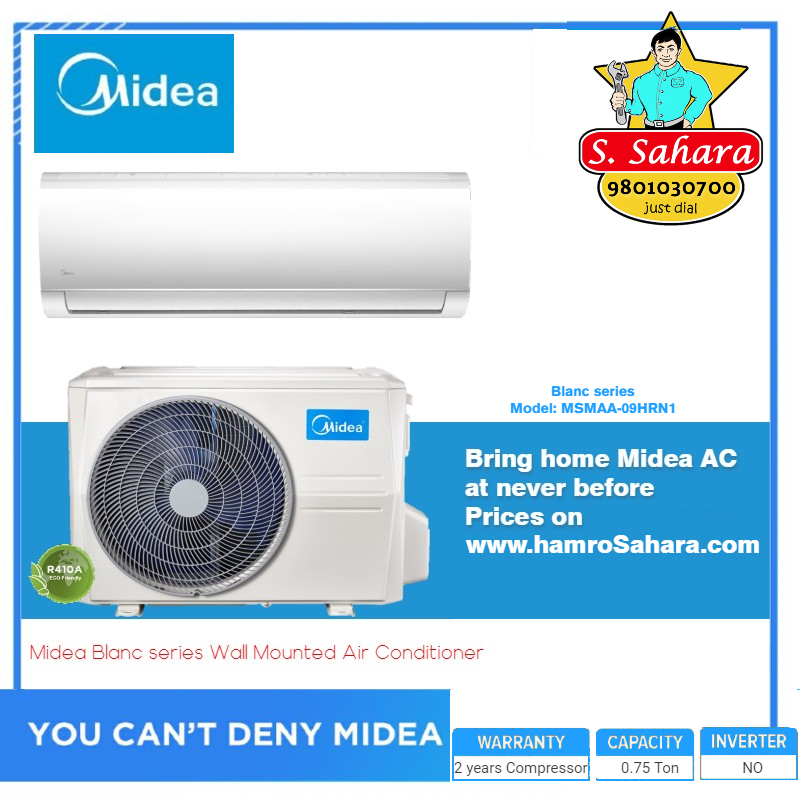

Midea Wall Mounted 0.75 ton Air Conditioner (Blanc series)

Out of stock

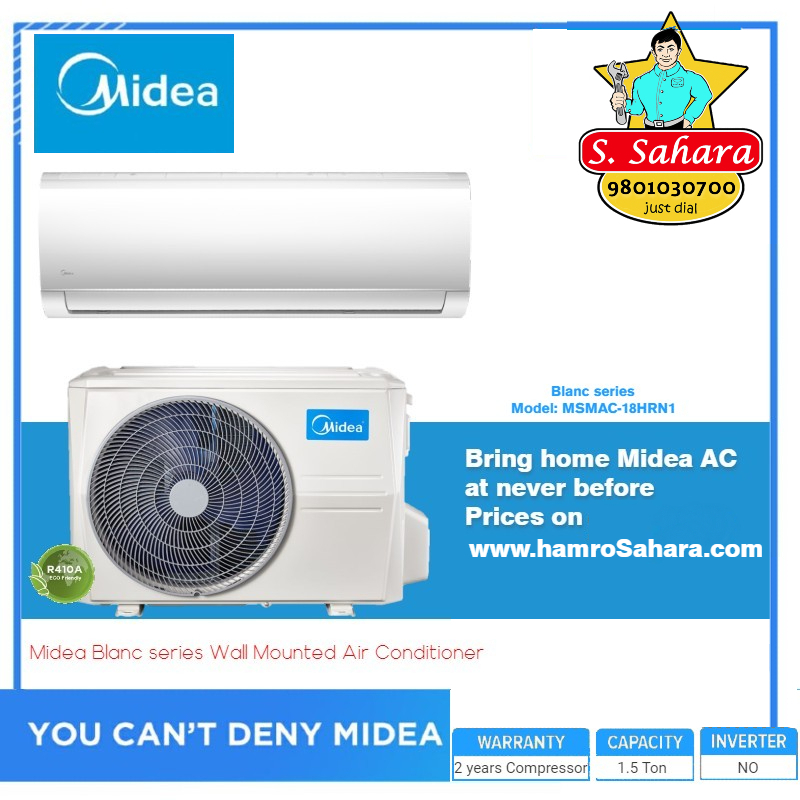

Midea Wall Mounted 1.5 ton Air Conditioner (Blanc series)

Out of stock

Midea Xtreme Save Series DC Inverter Wall Mounted Air Conditioner 1 ton | MSAGB-12HRFN8

In stock

Rated 4.76 out of 5

Midea Xtreme Series 0.75 ton Wall Mounted Air Conditioner | MSAGAA-09HRN1

Out of stock

Midea Xtreme Series 1 ton Wall Mounted Air Conditioner | MSAGAB-12HRN1

In stock

Midea Xtreme Series 1.5 ton Wall Mounted Air Conditioner | MSAGAC-18HRN1

In stock

Midea Xtreme Series 2 ton Wall Mounted Air Conditioner | MSAGAD-24HRN1

In stock